In today's highly competitive fashion industry, selecting the right clothing accessories is essential to ensure product quality and market competitiveness. However, finding the ideal material for performance and cost-effectiveness among the many options is not an easy task. Today we want to recommend to you is a particularly suitable for making all kinds of clothing thick wide stretch white cloth.

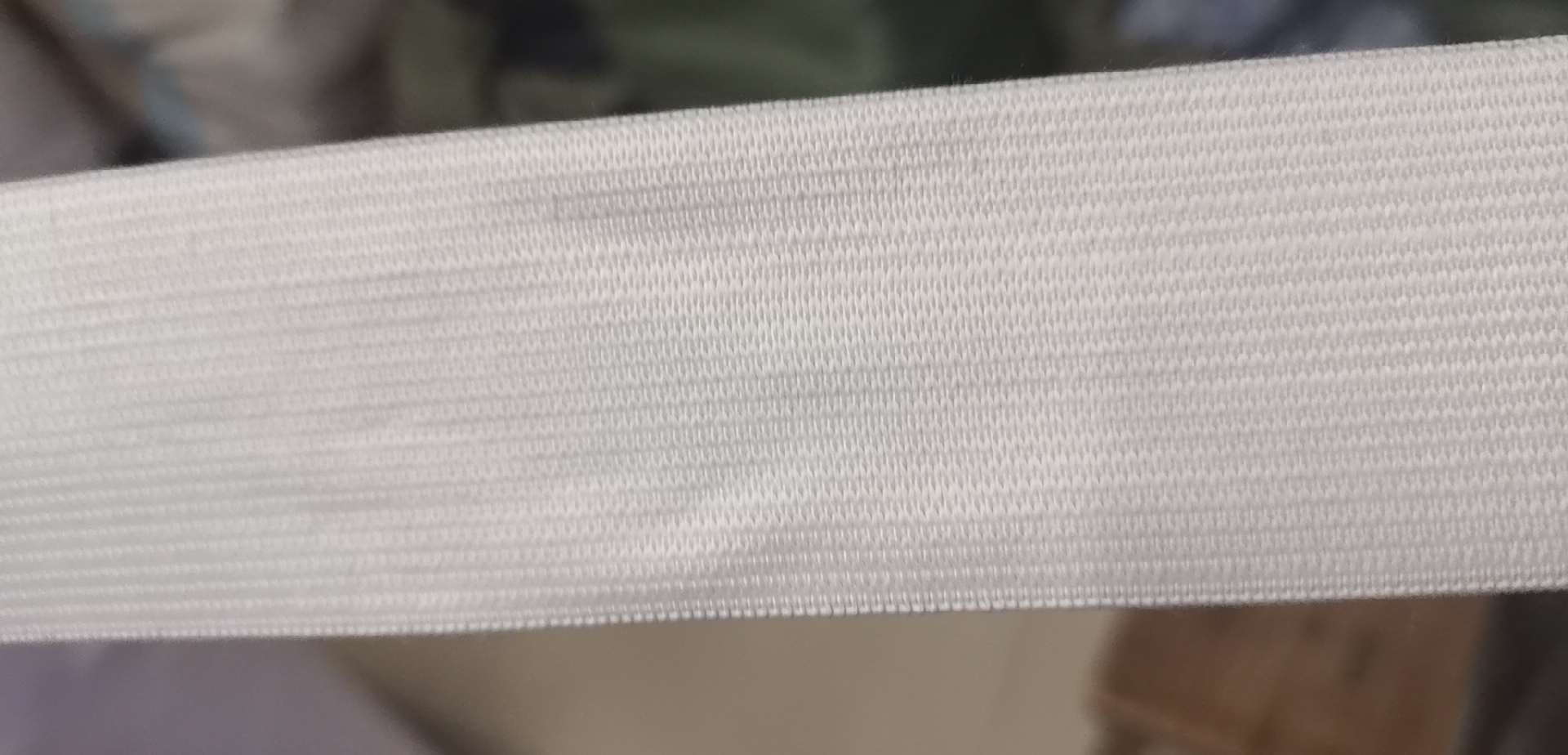

This fabric stands out for its excellent elasticity and durability, and can meet the needs of a variety of styles, whether it is general casual wear or professional sportswear that requires higher strength.

in-depth exploration of the characteristics of this innovative material and its scope of application, it is not difficult to find that its core advantages lie in several key factors: first, its thickness design provides good support, especially suitable for waist, cuffs and other parts that are easy to stretch and deform; Secondly, the ultra-wide specification reduces the workload of stitching and sewing, improves the production efficiency and reduces the defective rate; finally, the excellent elastic performance makes it more comfortable to wear.

In addition, because the white cloth adopts advanced production technology, even after many times of washing, it can still maintain the original shape without deformation and less fading, which has become one of the important reasons to attract buyers.

Compared with the traditional intermediary channel purchase method, the "factory direct supply" model undoubtedly brings significant cost savings to enterprises. By omitting unnecessary circulation expenses, consumers can not only enjoy a more attractive price level, but also ensure that every order is strictly controlled from the source.

Our production base is equipped with modern equipment and technical team support, committed to providing our customers with a stable and reliable service system while continuously improving their own management level to meet the challenges that may arise in the future.

To better understand how this high quality fabric was born, follow us behind the scenes to see the entire manufacturing process. Everything goes back to the stage of selecting raw materials-only cotton above a specific required grade can be used in the spinning process. The next step is to implement multiple dyeing and finishing procedures under precise temperature and humidity control until the final forming and packaging leaves the factory.

Each step requires experienced technicians to operate and monitor, and regularly sample test data feedback to adjust parameter settings to minimize the probability of error.

There are many successful examples of practical applications that can be used for reference. For example, a well-known brand sports pants series has adopted a large number of such new auxiliary materials instead of the old version of ordinary cotton lining structure, which obviously improves the ventilation and sweat-wicking function and prolongs the service life by nearly three times. In addition, some children's pajamas manufacturers have also reflected that customer satisfaction has increased significantly after switching to this product, and the number of complaints has dropped significantly, etc. Good evaluation information has emerged one after another.

This shows that choosing the right supplier cooperation can indeed help the brand establish a long-term competitive advantage position to a large extent.